The Ellison Lab researches industrial and floral hemp to support Wisconsinites growing this cutting-edge crop.

By Audra Koscik

In the 2010s, legal restrictions lightened on a controversial crop: hemp. For the first time in decades, farmers would be able to legally cultivate the crop in the U.S. following strict guidelines. The hemp industry in Wisconsin returned to full force but with some major challenges. To support new growers, the Ellison Lab at the University of Wisconsin-Madison began researching this promising crop.

The Ellison Lab is well-equipped to study crops like hemp. “Very broadly, we are an alternative crops lab where we look at newer, emerging crops that may have a niche market or a newer market in the case of hemp,” says Phillip Alberti, research program manager for the lab.

Hemp has a variety of evolving markets. Industrial hemp can be processed to create textiles, insulation, paper, and more. The seed collected from industrial hemp can be used for protein in yogurt parfaits and other foods. A wide variety of products from lotions to cookies can be made with cannabinoids, like CBD and THC, from floral hemp.

The Ellison Lab studies both industrial and floral hemp. “We’re trying to figure out which varieties grow well here, particularly for outdoor production, which a lot of the growers here would like to do,” explains Alberti.

A key to the Ellison Lab’s research is picking varieties that are complaint with government regulations. Hemp includes plants of Cannabis sativa which contains miniscule amounts of THC, the psychoactive compound found in cannabis. If the THC in hemp passes a certain threshold, the plant is considered “drug-type” cannabis or marijuana.

To remain compliant, every plot of hemp grown in Wisconsin must have less than 0.3% THC content, or the crop must be destroyed. “So, there is a heavy burden on the grower to make sure that happens,” says Alberti. “We’re trying to help lighten that burden by working with growers and working with other researchers across both academic and private sectors.”

Compliance is also an issue for growers because it impacts the profitability of the crop. “This is explicitly true in high cannabinoid hemp varieties where most growers want to allow them to go to full maturity in the field,” says Alberti. “Many varieties will reach the 0.3% cutoff for compliance well before they reach physiological maturity at flowering, which is when many other states or growers would be harvesting that material.”

To help growers harvest before their hemp surpasses 0.3% THC, the Ellison Lab helped create the Cannabinoid Hemp Database . This database has timelines of the development of chemicals like CBD and THC for different hemp varieties across the Midwest.

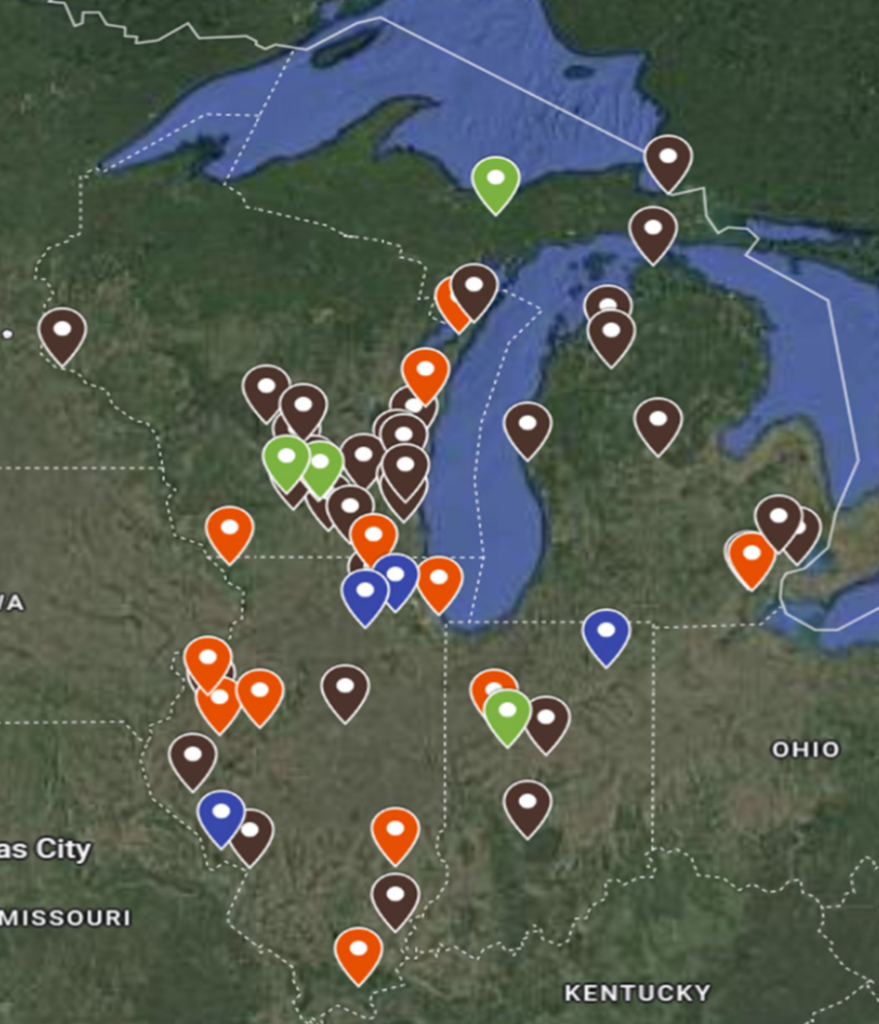

The Ellison Lab also helped establish a variety trial network called the Cultivar Check Program. It consists of over 20 research partners across the Midwest that collect data on agronomic performance, flowering dates, grower’s experiences, and compliance. “We’ve done a lot of the legwork to start to give people ideas of which varieties to grow here and when they should harvest them to make sure that they’re compliant,” says Alberti.

In addition to compliance, the Ellison Lab considers the end uses when studying hemp varieties and crop systems. Hemp can be used for a broad range of products from building insulation to cookies. As such, the varieties grown and how they are cultivated are very different.

Industrial hemp is grown for its grain, fiber, and hurd. The fiber is the outer part of the plant and used for items such as rope or textiles. The hurd is the pulpy inner part of the plant and is used for products like paper. In contrast, floral hemp is cultivated for its flower which is then often used to extract cannabinoids like THC and CBD.

Processors must separate the fiber from the hurd to use industrial hemp. This is an intricate process, especially for the fiber. For floral hemp, growers harvest the flower.

Industrial hemp is usually grown in rows similar to commercial row crop production systems such as corn or soybean, and growers can manipulate factors such as the spacing of the rows to impact how tall or thin the crop is. On the other hand, floral hemp focuses on the flower quality and emulates a high-input production system commonly used in horticultural crops like tomatoes or peppers.

The plethora of uses, and therefore varieties and cropping systems, creates a conundrum for the Ellison Lab. “I think one of the challenges is limited processing,” says Alberti. “The end use determines how we grow the crop.” However, since the hemp market is still growing, the uses and processors available are still emerging. “If we don’t have the processor or we can’t process the materials, then we can’t figure out how to better grow what we have,” says Alberti.

As such, part of the lab’s work is collaborating with processors. Many promising uses are developing. Hemp is now being used to create hempcrete, a non-structural insulation material. Additionally, a Wisconsin company Sativa Building Systems uses hemp hurd to create panels that are up-to-code for commercial uses, says Alberti. “We’re in this development stage,” he says. “I think folks are now starting to see the real benefits and potential for large scale commercial row cropping and consumer products via industrial hemp for grain, fiber, or dual-purpose production.”

As these markets grow, the Ellison Lab is keeping sustainability in mind. “We’re looking at sustainable management practices for hemp; how can we get the highest return on investment with the lowest inputs, but also the lowest impact on the on the environment and within our own fields?” Alberti says. To help answer this question, the Ellison Lab conducts studies such as their current cover crop and nitrogen rate interaction study with floral hemp.

The Ellison Lab also conducts unique research that builds off Wisconsin’s history with hemp. Wisconsinites grew hemp in the early 1900s. During WWII, the government commissioned growers to produce hemp which would be used to create items like rope or parachutes. “Here in Wisconsin, we were among some of the leaders of that production,” Alberti says.

“As part of our research, our lab has worked tirelessly to collect wild or ‘feral’ hemp seeds from all over the country to preserve and characterize the legacy hemp germplasm that exists. Quality and uniformity was quite variable, as you can imagine,” Alberti says, “but we are still using that for sequencing and hoping that we can tap into some of those older materials for genetic improvement.”

The Ellison Lab then combines the data collected from historic seeds with well-established hemp crops. “We have the best of both worlds,” says Alberti. “We’re developing a breeding program which is using desirable traits from those feral lines that are acclimated to this environment. And then we get to see how their commercial counterparts do and compare them alongside each other.”

Alberti is hoping to share the lab’s information widely with growers and across disciplines. This April, the Ellison Lab attended the first Cannabis Research Conference at UW-Madison, which connected scientists from pharmacy, psychology, tobacco, and health. “It’s kind of full circle of growing, then to processing, and then to impacts and clinical trials,” says Alberti. “How we can connect all the pieces of the puzzle and do it the right way, those are among the discussions that are happening here at UW-Madison.”

The Ellison Lab will also host a Hemp Research Field Day on August 21 at Arlington Agricultural Research Station. The field day is an annual event. “Over the years many of the people who have showed up have ultimately become growers for us or contributed to our projects in some way,” says Alberti. “We love how much we can have that engagement, and it ultimately gets people involved.”

2025 Ellison Lab Plant Growth

Photos by Phillip Alberti

End of June

Middle of July

Early August