By Audra Koscik

Cranberries are integral to Wisconsin agriculture. The U.S. is the world’s largest cranberry producer, and Wisconsin accounts for over half of U.S. cranberry production.

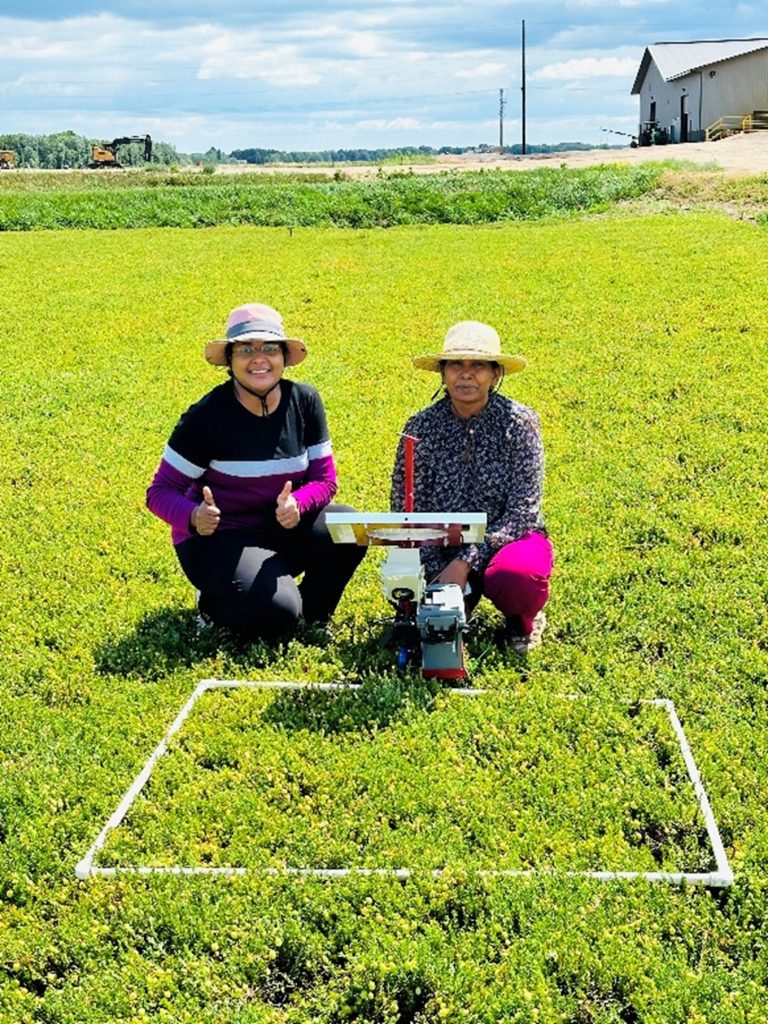

Given this, many scientists at the University of Wisconsin-Madison specialize in cranberries and carry out extensive research and outreach programs for cranberry growers. Dharani Suresh Babu, a graduate student co-advised by Jyostna Mura and Amaya Atucha, has joined this area of work.

Suresh Babu is a doctoral candidate majoring in horticulture with a minor in computer science. As such, she has a strong background in weaving together technology and agriculture. For her doctoral work, she was interested in creating technologies that would support cranberry growers.

To begin her research, cranberry growers were interviewed to identify their most significant needs. “They gave us a list, and we selected the top three based on the most pressing challenges shared by multiple growers – issues that, if addressed, could significantly improve cranberry production,” she says.

Not only did she interact with growers, but she also engaged with researchers and Extension workers. Through these conversations, she found that, while research had been conducted on older cultivars, there was little information available on the growth stages of many newer cultivars especially across the full growing season. Based on these insights, tracking the intricate growth stages of newer cultivars became a key focus of the research.

To do so, she needed a way to accurately monitor the cranberry crops. Cranberry is a very small crop, and the plant only grows a few millimeters in the first developmental stages. Additionally, as the plant keeps growing, the stages also become a little bigger. Given this, her team needed a camera that could focus on the minuscule changes and adapt its focus as the plant developed.

The camera had a few other hefty requirements. “We wanted the camera also to record the environmental variables like temperature, humidity, soil moisture, and things like that,” says Suresh Babu. Additionally, the camera needed to withstand extreme weather conditions from around April to October.

Her team also wanted the camera to be environmentally friendly. “We don’t want to use lead batteries or anything,” she says. They wanted the entire system to be solar powered.

Lastly, she wanted the camera to be cost effective. The cameras on the market were often quite expensive. “There was one camera costing around $1,500,” she says. “Whatever we developed maximum cost should be around $175.”

Given all of these requirements, her team decided to build the camera themselves. They used Raspberry Pi devices. These small computers are about the size of a credit card. They are often used by developers as they are fairly affordable and adaptable to many uses.

Suresh Babu was well-equipped to handle the software and data aspects of the camera but needed assistance with the electronics. She collaborated with Andrew Maule, a current PhD student in the Plant Breeding and Plant Genetics program, and Andrew Engedal, a former UW–Madison undergraduate student, to build the camera system. “They took care of the hardware, and I handled the software,” she says.

Suresh Babu and her team were able to develop a camera that could meet all of their requirements. “It was definitely not an easy feat,” she says. “We developed a lot of prototypes. It’s been like three to four years of hard work.”

Her team installed the cameras at the beginning of the growing season in a Wisconsin cranberry marsh and retrieved them at the end. The cameras capture images every 30 minutes 24/7. “I would say we have collected like 13 terabytes of data. That is huge data actually,” says Suresh Babu.

To process this data, Suresh Babu used her computer science skills. “If I sit still and use all these traditional image processing algorithms, I will say it’s going to take forever and ever for me to complete an analysis,” she says. As such, she decided to code an AI model to process the images.

“I’m developing customized cranberry-based AI models like vision transformers which can process this huge data set and give us our desired output which is the phenological stages for all those cranberry cultivars,” says Suresh Babu.

She can alter this AI model to capture how the cultivars vary depending on the site they grow in. “We are giving information to the growers which is cultivar specific and site specific,” she says. “So, for example, I could say, ‘cultivar 1 in this location will take so many days from one stage to another stage. But this is not the same as the cultivar in the other location.’”

Growers can use this information to optimize their management practices. “Growers are renting combines or harvesting machines and bee pollination based on a very common time,” she explains. “But sometimes one cultivar will move in a different time, and another cultivar will move in a different time. So, the waiting period will cost more money for growers.” Using Suresh Babu’s technology, growers can optimize their management practices and save money.

Growers can also use this information to specifically target when applying nitrogen. “So, in a way, growers will be able to achieve both sustainability and profitability,” says Suresh Babu.

Another issue cranberry growers face is identifying which parts of their field are under stress. Often, a small section of a field will experience stress such as nutrient deficiency, disease, or pest attack. These stresses can be difficult for the grower to see until it’s too late. If the grower does see the stressor, they may apply a blanket application to the whole field which can be environmentally and financially costly.

Luckily, researchers have discovered ways to detect which sections of a field are under stress using infrared radiation.

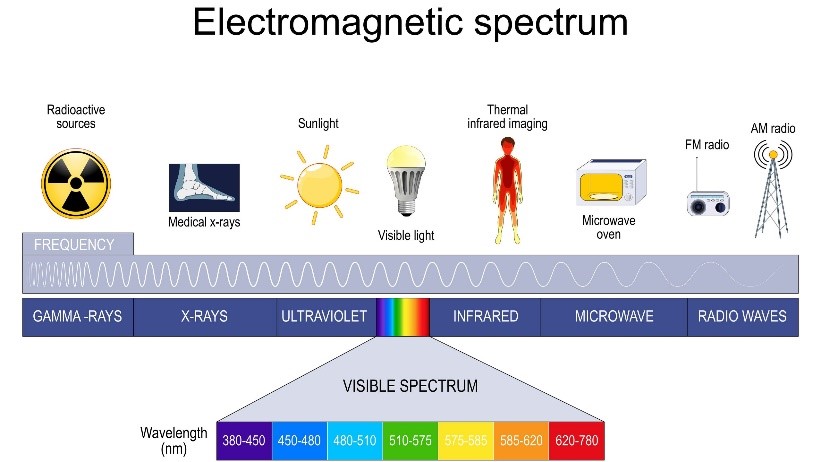

Infrared radiation is a form of light outside the range humans and many cameras can see. “We have our phones, and we capture images, right?” Suresh Babu explains. “Whatever images we capture using our phones are called visual or RGB images.” RGB is visible to humans, but there is a much broader spectrum of light invisible to us.

“Imagine something on the electromagnetic spectrum – like UV rays, x-rays, gamma rays,” she explains. “After visual range, which is called RGB, there is something called infrared range. And that infrared range is not visible to our eyes; we can just feel it in the form of heat energy.”

Plants receive ultraviolet (UV) rays from the sun, and the plant in turn emits infrared radiation. However, the plant’s infrared radiation changes if it is in distress. “Basically, if the plant is stressed, it should give less infrared,” says Suresh Babu. “If the plant is not stressed, it should give more infrared.”

Researchers have applied this concept to many crops to develop remote sensing technologies. These tools capture a field’s infrared data to compare which sections are healthy and which are under stress. This method often identifies signs of stress before they become visible to the human eye.

Remote sensing has not been widely established in cranberry production. The limited remote sensing work that has been done primarily involves hyperspectral sensing which, while highly precise, is also expensive and complex to process. “It requires a high-performance computer and a qualified, trained expert to handle the data,” Suresh Babu explains.

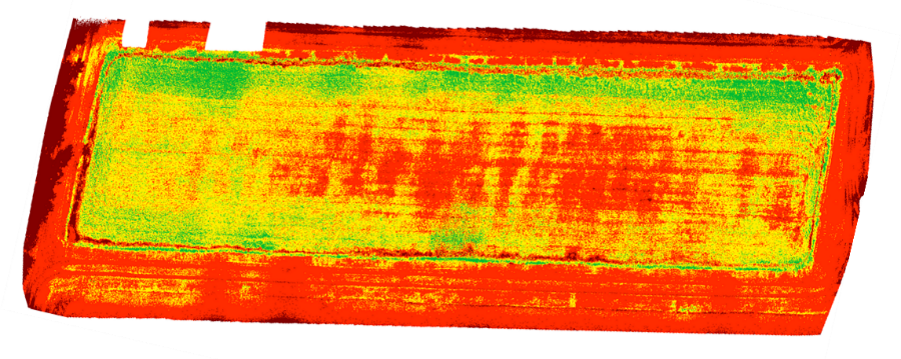

She wanted to develop a solution that would be more affordable and accessible. Instead of relying on hyperspectral technology, Suresh Babu and her team utilized commercially available drones equipped with multispectral and thermal sensors to collect data.

“The drone cost less than $10,000, and images captured by this drone can be processed on a regular laptop,” she says. “And, with a sufficient amount of training, growers can do it on their own.”

She has already used this technology to assist growers directly in the field. In one case, a grower she was working with to implement multispectral drone-based remote sensing had accidentally missed a small section of the field during a nitrogen application. This section of the field was clearly visible in the remote sensing data Suresh Babu collected.

Suresh Babu and her team collected soil samples and drone imagery to investigate the issue. “There was a nitrogen deficiency, which matched exactly with the patterns shown in my multispectral map,” she says. “We shared this information with the grower, who was very pleased. Since we were able to identify the issue early, the grower could take mitigation measures before the stress spread or became more severe.”

Apart from this, Suresh Babu has also developed an AI-based web application to help growers determine the optimal time for harvesting. The existing technologies are often expensive, time-consuming, and require some programming knowledge to operate. Suresh Babu aimed to build a user-friendly web app that delivers instant and accurate results and can run seamlessly on electronic devices such as mobile phones, laptops, desktops, and tablets. Additionally, because cranberry marshes are often located in remote areas with limited network connectivity, she designed the app to function efficiently even with low signal strength. Suresh Babu is actively gathering feedback from users and working on continuous improvements to make the app even more effective and accessible.

Suresh Babu believes that this app and the other technologies will be used by a broad audience including growers, breeders, extension workers, and researchers. She also hopes these technologies can be extended to other specialty crops beyond cranberries.

These cutting-edge technologies are made possible by many collaborators. Suresh Babu says, “I am grateful to my advisers for their constant support and guidance, and to our undergraduate and graduate students and my lab team members for all their support without whom this research would not have been possible. I am also deeply thankful to all the cranberry growers for their ongoing support and encouragement for my research.”

Suresh Babu and her team are excited to continue to work with growers as they implement and develop new technologies. “Growers can always reach out to us,” says Suresh Babu. “We are very happy to work with them.”